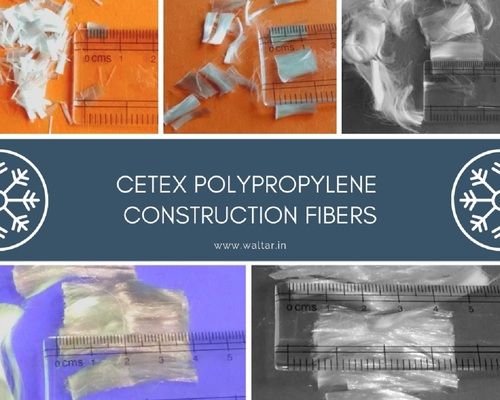

PP Fiber

Product Details:

PP Fiber Price And Quantity

- 20 Kilograms

- 137 INR/Kilograms

PP Fiber Trade Information

- JNPT Nava Shewa, India

- Yes

- Free samples available with shipping and taxes paid by the buyer

- 25kg Bags or packing available as per requirement

- Australia South America Eastern Europe Western Europe Middle East Central America Asia North America Africa

- All India

- ISO 9001 2015

Product Description

CETEXpolypropylene PP Construction fibers are hydrophobic which do not absorb thewater and are non corrosive Moreover the polypropylene fibers haveexcellent resistance against alkali chemicals and chloride and have low heatconductivity By these characteristics polypropylene fibers have therefore nosignificant effect on the water demand of the fresh concrete They do notintervene in hydration of cement and hence do not influence unfavorably theeffects of all constituents in the concrete mixture

Polypropylene is the lightest syntheticpolymer Hence the count of fiber for a given weight is maximum in case ofpolypropylene It is 52 lighter than polyester and 26percent lighter thannylon and acrylic Hence polypropylene fibers are ideal for reinforcement CETEX fibers are treated with specialchemicals for better dispersion and bonding of the fiber with the cementitiousmatter CETEX construction fibersare compatible with all concrete admixtures and performance enhancingchemicals CETEX fibres are easy touse and they disperse easily

SPECIFICATION OF CETEXPOLYPROPYLENE FIBRES

Material VirginPolypropylene PP

Length 612 24 36 50

Melt Point 162Degree C

Specific Gravity 091

Ignition Point 360C

Thermal Conductivity Low

Electrical Conductivity Low

Alkali Resistance 100 percent Alkali Proof

Acid Salt Resistance High

Diameter approx 19 to 40 micron

Aspect ratio approx 215 to 1250

DIRECTION OF USE

For onsitemachine mixing

Small quantity of water is dosed in empty drum to clean the drumafter each batch Add fiber in the rotating drum Then addchipssandcementwater in the concrete mixer and continue normal operation

Fordosing in Ready Mix Truck

Add fibers in small lots in the rotating drum After dosing iscomplete allow extra 2030 revolutions of drum at maximum RPM

ForManual Mixing CPP0612

Put fibers in a bucket of water and stir it so that fibersdisperse in water Spread the water and fibre mixture on the dry cementatiousmix

DOSAGE

For crack prevention 500to 1000gmm3

For Fire Protection of Concrete 10 30 Kgm3

As primary reinforcement 10 40 Kgm3 depending onconditions required

The above mentioned dosage is just a guideline It is recommendedto optimize the dosage depending on the requirement

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'PP Construction Fiber' category

|

XETEX INDUSTRIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free